google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Green hydrogen production and electrolyzer technology - new energy - YMUS ultrasonic spraying

Green hydrogen production refers to the use of renewable energy to produce hydrogen to replace traditional fossil fuel hydrogen production methods. Among them, electrolyzer technology is a common green hydrogen production method.

Electrolyzer technology produces hydrogen and oxygen through the process of electrolyzing water. In an electrolyzer, water is decomposed into hydrogen and oxygen by the action of an electric current. The electricity used in this process generally comes from renewable energy sources, such as solar or wind power. Therefore, the hydrogen produced through electrolyser technology is green and is also known as renewable hydrogen.

Electrolyser technology is relatively mature and scalable to large-scale production. It has the following advantages:

- Using renewable energy as a source of electricity reduces dependence on fossil fuels.

- Electrolyser technology can be flexibly adapted to fluctuations in electricity supply and therefore can be better used with renewable energy generation facilities.

- Efficiency and durability can be continuously improved by changing electrolyzer design and material selection.

However, current electrolyzer technology still faces some challenges, such as high cost, energy loss, corrosion resistance and stability of electrolyzer materials. However, as technology continues to advance and costs decrease, green hydrogen production and electrolyser technology are expected to play a more important role in the future, supporting the transition to sustainable energy and clean energy.

Ultrasonic spray technology is a high-precision spray technology that uses ultrasonic vibration to spray coating materials onto the target surface. The application of this technology in electrolyzer technology can help the development of electrolyzers.

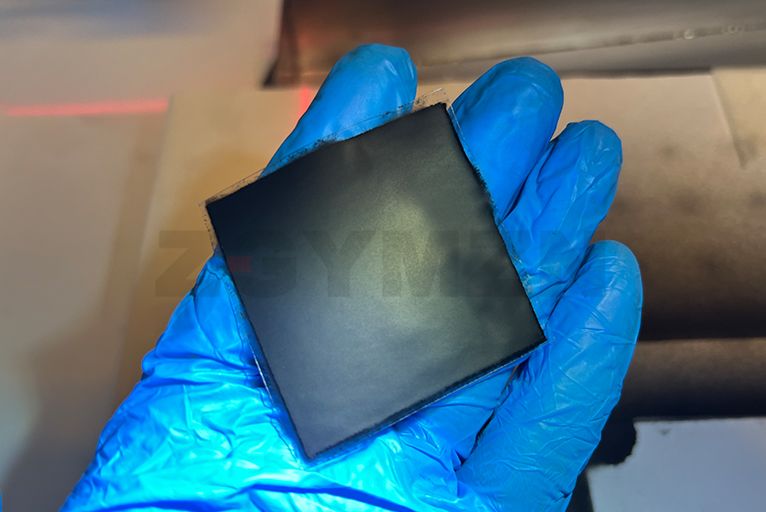

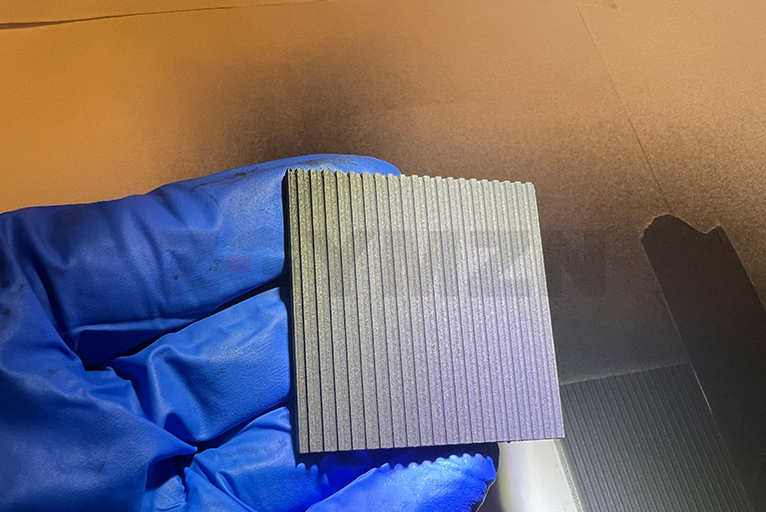

1. Electrolytic cell coating: In order to improve the corrosion resistance and service life of the electrolytic cell, it is often necessary to coat the internal or external surface of the electrolytic cell with special materials for protection. Ultrasonic spray technology can accurately spray coating materials to ensure uniform coverage and high adhesion.

2. Hydrogen and oxygen collector plate coating: In the electrolyzer, hydrogen and oxygen need to be collected and discharged through the collector plate. In order to improve the efficiency and stability of the current collector plate, it is often necessary to apply a special coating on the current collector plate. Ultrasonic spray technology can accurately spray these coatings to ensure the uniformity and quality of the coating, thereby improving the efficiency of the electrolyzer.

3. Conductive filler coating: In electrolytic cells, it is sometimes necessary to coat conductive materials on the electrodes or electrolyte channels inside the electrolytic cell to improve the conductive performance of the electrolytic cell. Ultrasonic spraying technology can evenly spray conductive filler materials at the target location to ensure the bonding force between the material and the substrate and improve the performance of the electrolytic cell.

By applying ultrasonic spray technology, electrolyzer technology has the following advantages:

- Improve the uniformity and adhesion of the coating and increase the service life of the electrolytic cell.

- Improve the efficiency and stability of the collector plate and improve the efficiency of the electrolytic cell.

- Improve the conductivity inside the electrolytic cell and improve the performance of the electrolytic cell.

The precision and controllability of ultrasonic spray technology make its application in electrolyzer technology very promising and help improve the reliability and efficiency of electrolyzers.