google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation of ZnO hydrophobic coating - new energy - YMUS ultrasonic spraying

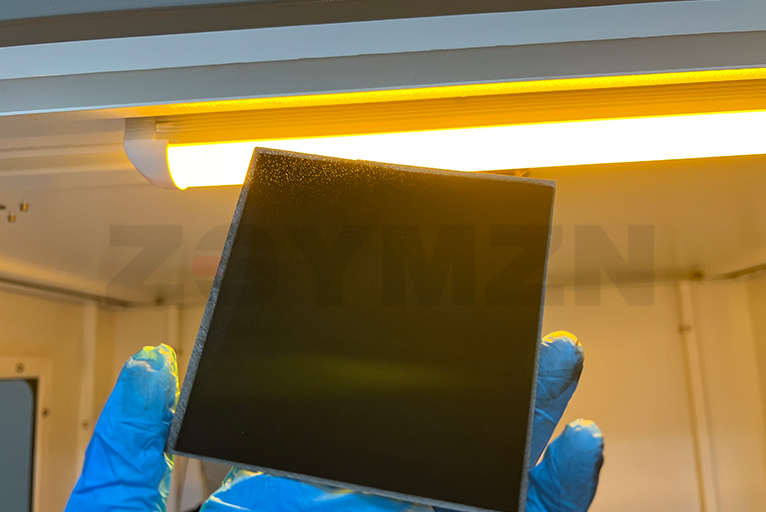

Ultrasonic spraying technology has broad application prospects in preparing catalyst coatings on hydrophobic carbon paper. As the demands for energy transition and environmental protection increase, there is an increasing demand for efficient and low-cost catalyst preparation technology. As an excellent carrier material, hydrophobic carbon paper has high specific surface area, good electrical conductivity and chemical stability, and is very suitable for the preparation of catalyst coatings. Ultrasonic spraying technology has the advantages of fast preparation speed, low cost, and good process controllability, so it has broad application prospects in the field of catalyst preparation.

Ultrasonic spraying is a coating technology that uses ultrasonic energy to break liquid into tiny particles and spray them onto the surface of the substrate. During the spraying process, the ultrasonic generator generates high-frequency vibration, causing the liquid to form fine mist particles at the nozzle. These particles evenly adhere to the surface of the substrate under high-speed movement, forming a uniform coating. Because the energy of ultrasonic waves can effectively break up large particles, a more delicate and uniform coating can be obtained.

● Energy field: Catalyst coatings prepared on hydrophobic carbon paper have important applications in the energy field, such as fuel cells, electrolysis of water for hydrogen production, etc. There is a high demand for efficient and stable catalysts in these fields.

● Environmental field: Catalyst coatings prepared on hydrophobic carbon paper can also be used in environmental fields, such as electrochemical sewage treatment, exhaust gas treatment, etc. Catalyst coatings can improve reaction efficiency and selectivity, reduce energy consumption and pollutant emissions.

● Chemical industry: The catalyst coating prepared on hydrophobic carbon paper can also be used in catalytic reactions in the chemical industry, such as organic synthesis, catalytic hydrogenation, etc. Catalyst coating can increase reaction rate and product selectivity, reduce reaction temperature and catalyst dosage.

◆High stability High stability

Made of high-performance titanium alloy and stainless steel, it has strong adaptability, corrosion resistance, no pressure, no noise, no nozzle wear and clogging, and high uniformity of atomized particles.

◆Materials in environmental protection

The impact force of the spray is very small and will not cause liquid splashing, which can reduce the waste of raw materials and air pollution caused by back spray. The coating utilization rate of ultrasonic spraying is more than 4 times that of traditional two-fluid spraying.

◆High controllability

It can accurately control the atomization flow, low-flow continuous spray, and the spray shape is easy to control and shape (add a spray mechanical arm), and is suitable for industrial fields. Through combination, the atomization volume can meet any user requirements.

◆Easy to maintainEasy to maintain

The liquid is transferred to the spray head through its own gravity or a low-pressure pump and achieves continuous or intermittent atomization. No blockage, no wear, no noise, no pressure, no moving parts. No cooling water is needed during atomization, low energy consumption, and simple equipment. , Low failure rate, the ultrasonic nozzle has a self-cleaning function and requires no daily maintenance.

◆Widespread use

Ultrasonic spraying equipment is mainly used in fuel cells, thin film photovoltaic cells, thin film solar coatings, perovskite solar cells, solar cells, graphene coatings, silicon photovoltaic cells, glass coatings, electronic circuits and other industries. The nozzle can be applied to a variety of solutions, and even sewage, chemical liquids, and low-viscosity oil mucus can be atomized and sprayed.