google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation of titanium anode coating for water electrolysis - hydrogen energy - YMUS ultrasonic spraying

As the global demand for clean energy increases, hydrogen production technology is widely used in the fields of energy conversion and storage. As a commonly used water electrolysis hydrogen production technology, water electrolysis titanium anode coating has the advantages of high efficiency, environmental protection, low cost, etc., and is regarded as an important part of the hydrogen production industry.

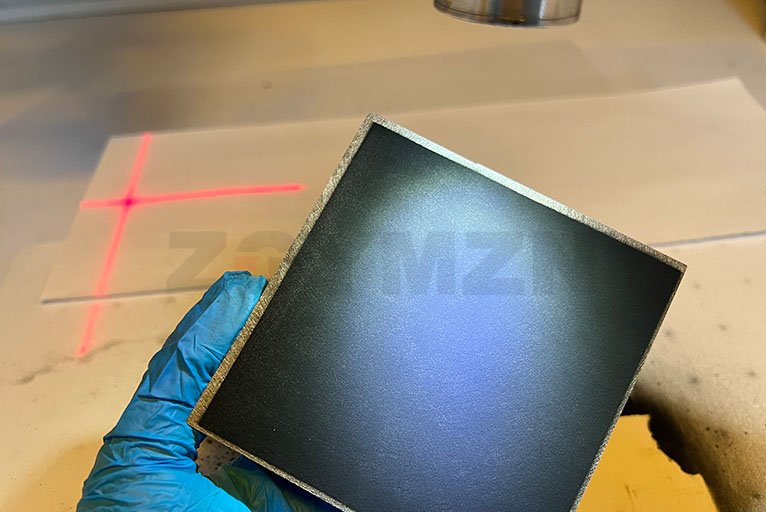

Ultrasonic spraying technology has advantages in titanium anodes for water electrolysis and can be used in fields such as water electrolysis for hydrogen production, fuel cells, and electrochemical sensors to improve performance and reliability in various application scenarios.

1. Hydrogen production by water electrolysis: Water electrolysis is a process that decomposes water into hydrogen and oxygen by applying electricity. Ultrasonic spraying technology can be applied to titanium anode coatings for water electrolysis to improve electrolysis efficiency and stability and promote the development of green hydrogen energy technology.

2. Fuel cell: A fuel cell is a device that converts hydrogen or other combustible gases into electrical energy. In fuel cells, ultrasonic spray technology can be applied to the coating of titanium anodes to improve battery performance and life.

3. Electrochemical sensor: An electrochemical sensor is a device that uses electrochemical principles to detect and measure chemical substances. Ultrasonic spraying technology can be applied to titanium anode coatings in electrochemical sensors to improve the sensitivity and response speed of the sensor.

1. Uniformity: Ultrasonic spraying can produce a uniform coating and form a uniform film on the surface of the titanium anode, providing higher efficiency and stability.

2. Adhesion: It can improve the adhesion between the coating and the anode surface, reduce the risk of coating peeling, and improve the stability and durability of the coating.

3. Cost-effectiveness: Compared with traditional coating methods, ultrasonic spray technology has lower costs, saves resources and materials, and improves production efficiency.