google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

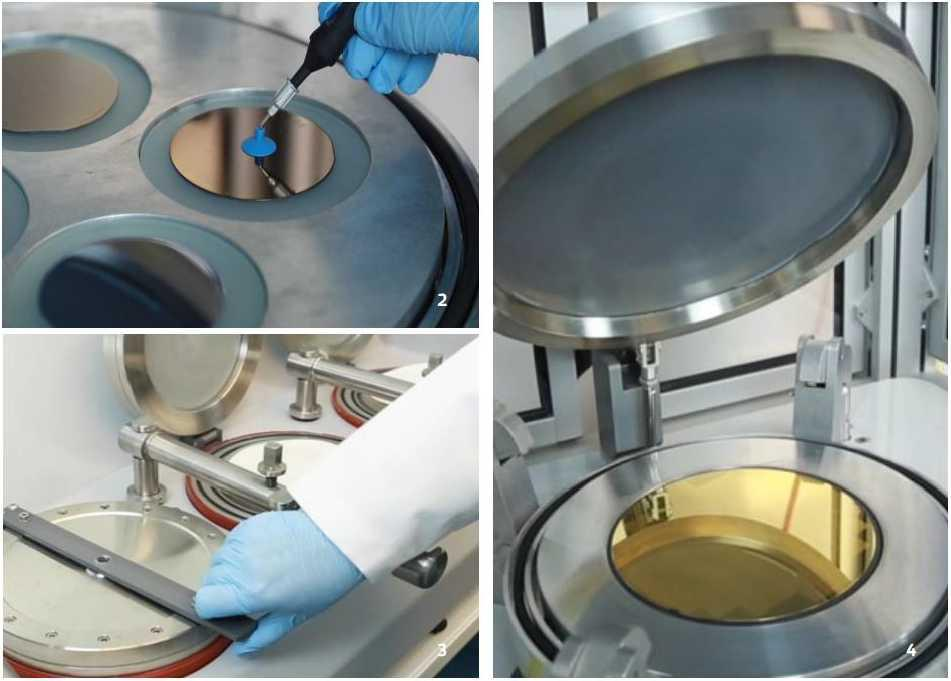

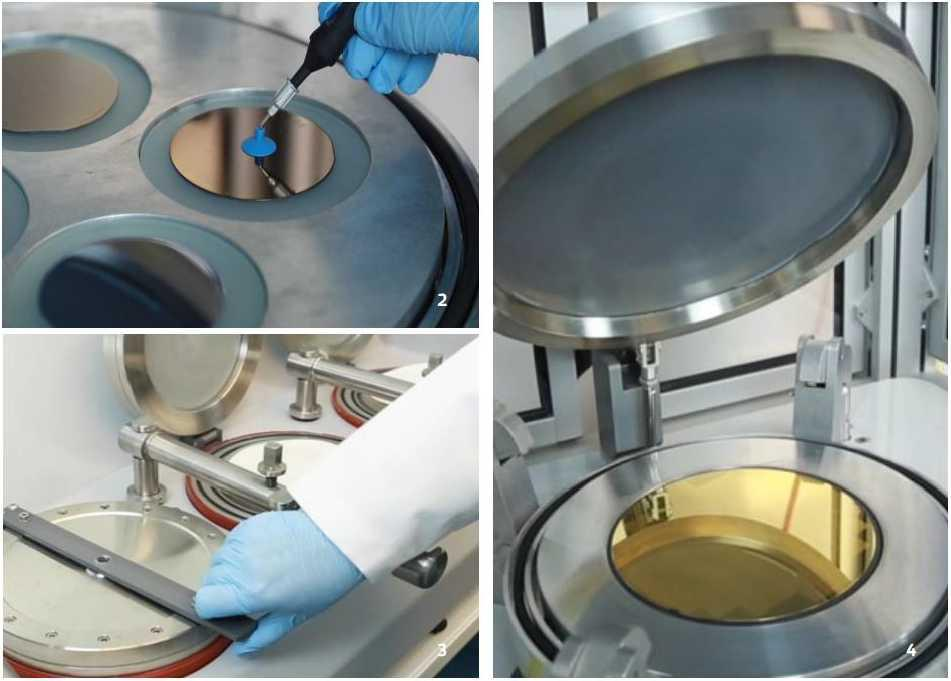

Wafer Bonding Machine - Modular wafer bonding system

Wafer Bonding Technology refers to the close combination of two homogeneous or heterogeneous chips that have been mirror-polished through chemical and physical action. After wafer bonding, the atoms on the interface react under the action of external forces to form covalent bonds and combine into a whole, and make the bonding interface reach specific bonding strength.

Equipment characteristics

● Modular configuration

● Automatic process cycle

● Handle 2-8 inch products

● Ultra-high wafers support disc parallelism

● Low/medium yield is used in production tools

● Industry-standard safety features

● Multi-functional scheme creation and automation mode

● Data collection and export

● Touch screen user interface

Advantages and characteristics

● High precision: The wafer bonding machine has a high precision, the diameter and thickness of each bonded wafer can reach the precise standard;

● High reliability: The key components of wafer bonding machine are all international first-class products, to ensure the high reliability of the equipment;

● High speed: The wafer bonding machine works fast and can process a large number of wafers in a short time;

● High automation: automatic control system can eliminate manual manipulation, greatly improve the work efficiency;

Technical parameter

| Chamber size | ≤12 inches downward compatible |

| Temperature range | ≤300℃ |

| Cycle time | 0-60min adjustable |

| Power supply | 220V |

Wafer Bonding Machine - Modular wafer bonding system

Wafer Bonding Technology refers to the close combination of two homogeneous or heterogeneous chips that have been mirror-polished through chemical and physical action. After wafer bonding, the atoms on the interface react under the action of external forces to form covalent bonds and combine into a whole, and make the bonding interface reach specific bonding strength.

Equipment characteristics

● Modular configuration

● Automatic process cycle

● Handle 2-8 inch products

● Ultra-high wafers support disc parallelism

● Low/medium yield is used in production tools

● Industry-standard safety features

● Multi-functional scheme creation and automation mode

● Data collection and export

● Touch screen user interface

Advantages and characteristics

● High precision: The wafer bonding machine has a high precision, the diameter and thickness of each bonded wafer can reach the precise standard;

● High reliability: The key components of wafer bonding machine are all international first-class products, to ensure the high reliability of the equipment;

● High speed: The wafer bonding machine works fast and can process a large number of wafers in a short time;

● High automation: automatic control system can eliminate manual manipulation, greatly improve the work efficiency;

Technical parameter

| Chamber size | ≤12 inches downward compatible |

| Temperature range | ≤300℃ |

| Cycle time | 0-60min adjustable |

| Power supply | 220V |

Heat transfer

Heat Transfer is a cooling oil used in YMJH systems;

Mounting adhesive

A range of sealers used to bond semiconductor, optical and geological samples;

Glass microscope slide

Glass microscope slides are used to fix thin rock, cement and soil sections;

Slide cover slide

Glass cover slides protect valuable thin sections and improve optical sharpness of transmission microscopy;