google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Customized vacuum plasma surface treatment system to improve the surface hydrophilic energy, suitable for IC packaging lead frame on the glue loading, chip bonding and plastic sealing process before cleaning.

PLASMA PROCESSING SYSTEM

ON-LINE VACUUM PLASMA PROCESSING

YMAPS-ZXV600

SCOPE OF APPLICATION

IC packaging lead frame on the glue sheet, chip bonding and plastic sealing process before cleaning.

TECHNIQUE PARAMETERS

| Project | Specification |

| Feeding and discharging mode | Automatic feeding and discharging line |

| Discharge structure | Vacuum capacitive glow discharge |

| Processing temperature | ≤50℃ |

| Number of plates in a single processing | 2 slices |

| Equipment capacity | Theoretical value ≥90 load plate/hour |

| To purify the protective | One hundred level purification and filtration system |

Device Features

The plasma is uniform, the cleaning effect is stable and the time is long

No pollutant emissions, no environmental concerns

No damage to the surface of the material

Good processing effect, stable operation, simple operation

Low maintenance cost

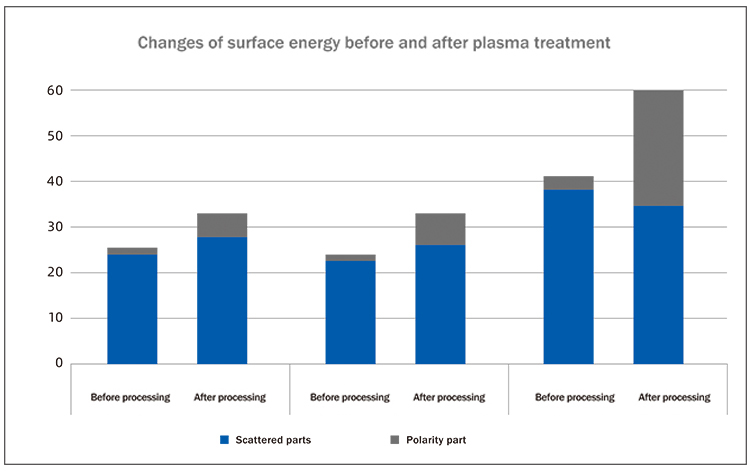

PRETREATMENT OF PLASMA

Plasma pretreatment is used to measure the surface tension of the material, and the influence of plasma equipment on the surface energy of the material is analyzed by measuring the parameters such as ink and contact Angle.

APPLICATION

● Medical Industry ● semiconductor industry ● Display industry

● Aerospace ● Automobile Industry ● Lithium Battery Industry

● Cable Industry ● glass industry ● Plastics industry

PLASMA PROCESSING SYSTEM

ON-LINE VACUUM PLASMA PROCESSING

YMAPS-ZXV600

SCOPE OF APPLICATION

IC packaging lead frame on the glue sheet, chip bonding and plastic sealing process before cleaning.

TECHNIQUE PARAMETERS

| Project | Specification |

| Feeding and discharging mode | Automatic feeding and discharging line |

| Discharge structure | Vacuum capacitive glow discharge |

| Processing temperature | ≤50℃ |

| Number of plates in a single processing | 2 slices |

| Equipment capacity | Theoretical value ≥90 load plate/hour |

| To purify the protective | One hundred level purification and filtration system |

Device Features

The plasma is uniform, the cleaning effect is stable and the time is long

No pollutant emissions, no environmental concerns

No damage to the surface of the material

Good processing effect, stable operation, simple operation

Low maintenance cost

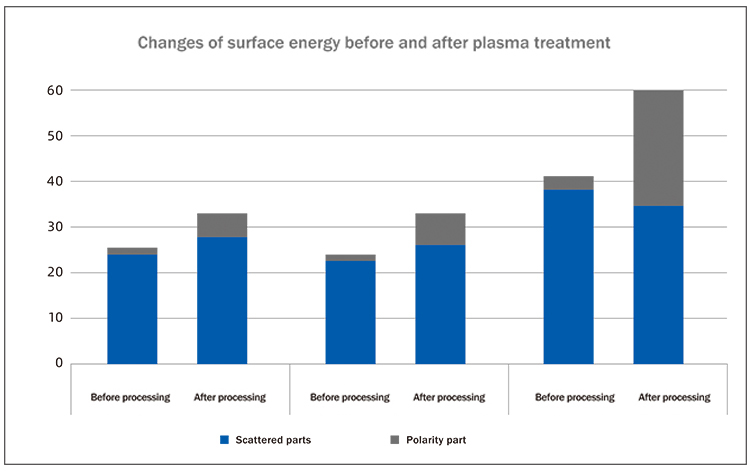

PRETREATMENT OF PLASMA

Plasma pretreatment is used to measure the surface tension of the material, and the influence of plasma equipment on the surface energy of the material is analyzed by measuring the parameters such as ink and contact Angle.

APPLICATION

● Medical Industry ● semiconductor industry ● Display industry

● Aerospace ● Automobile Industry ● Lithium Battery Industry

● Cable Industry ● glass industry ● Plastics industry