google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

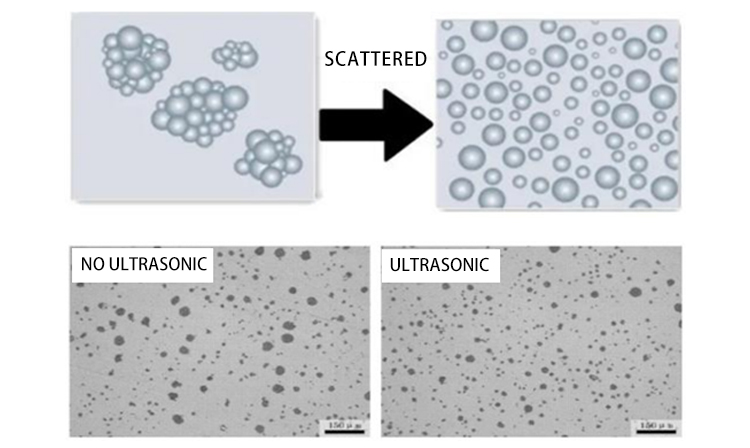

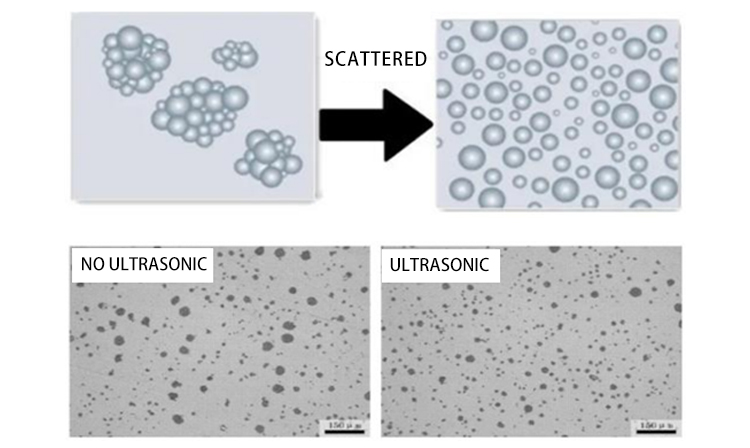

The ultrasonic dispersive liquid storage barrel can realize the on-line dispersion and stirring of the nano-solid particle dispersive liquid, and avoid the agglomeration and precipitation of the dispersive liquid in the process. The effect of ultrasonic on the suspension of solid particles in liquid or emulsion (that is, the suspension of two liquid substances without mixing with each other) is worthy of attention.

Ultrasonic spray coating

Disperse liquid storage drums

YMUS-FSJB2L

* Nanometer and micron suspensions are dispersed and mixed

The ultrasonic dispersed liquid storage barrel can realize the nano solid particles The dispersion solution is distributed online and stirred to avoid dispersion in the process Liquid agglomeration and precipitation, ultrasonic on liquid or emulsion A suspension of solid particles, ie two liquid substances suspended from each other But not mixed) deserves attention. Ultrasonic wavelength division The dispersive system acting in these suspensions will produce high strength Microjets, but not cavitation, which would have produced The effect of fun. We will detect solids of different sizes A suspension of particles, they're going to be divided into parts,Particles of the same size will be evenly distributed in the liquid.And compared to particles that have not been sonicated, this The particles stay suspended longer. Ultrasound Dispersion is a liquid medium in which a high frequency is added Ultrasonic vibration. Since ultrasound is a mechanical wave, it is not affected by molecules Absorption, which initiates the vibrational motion of molecules as they propagate.Cavitation effect, that is, high temperature, high pressure, micro jet, intense Additional effects such as vibration increase the distance between molecules The average distance, which eventually causes the molecule to break up. Ultrasonic transient The pressure released between the particles breaks the van der Waals forces between the particles,Making the particles less likely to stick together.

Ultrasonic cavitation process

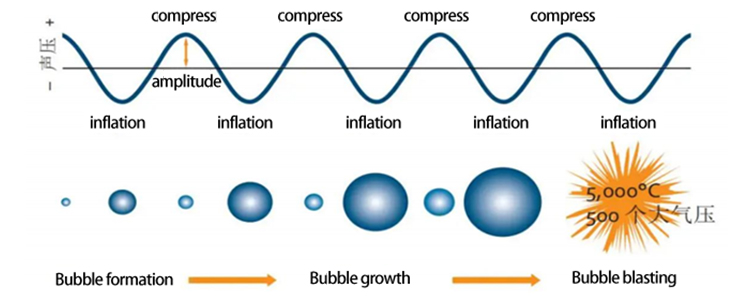

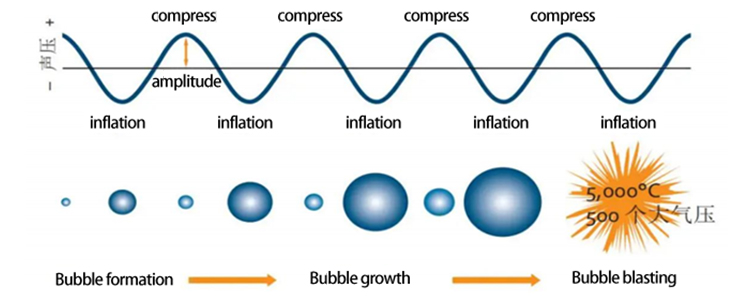

In chemistry, "acoustic cavitation" refers to the formation, growth and implosion of tiny bubbles, cavitation bubbles by compression clasps The expansion cycle consists of a compression loop that causes the positive pressure in the liquid to push the molecules together. In contrast, the expansion cycle Causing negative pressure to pull the molecules away from each other, once the bubbles grow very rapidly until they can no longer absorb the ultrasound Of energy. In this case, liquid will pour in and the bubble will burst. The whole process destroys the liquid phase Student: Student attraction. The cavitation bubbles burst very quickly, these tiny bubbles formed during the ultrasonic treatment It raises the temperature of the fluid around the chamber and creates local hot spots. But the area is so small as toAs for the heat dissipating very quickly. On the other hand, very high pressures are generated during bubble bursting, i.e., approx 1,000 atmospheres. Although the extreme conditions are very limited, ultrasonic treatment produces poles in cold liquids End physical and chemical conditions.

Technical parameters

◆ Product type: ultrasonic dispersed liquid storage barrel

◆ Frequency: 40KHz

◆ Capacity: 0.5-5L

◆ Solution conversion rate: ≥95%

◆ Solution viscosity: ≤50cps

◆ Radiation amplitude: 5-120μm

◆ Solution mixing type: many kinds (customized)

◆ Maximum pressure: < 8bar

◆ Rated power: 1000W

◆ Input voltage: 220V± 10%, 50/60Hz

◆ Transmitter material: titanium alloy

◆ Components: ultrasonic generator, special ultrasonic transducer, special amplitude rod, tool head, shell,

◆ Connecting cables, etc.

◆ Durable temperature: 0~80℃ liquid

◆ Ultrasonic generator: full digital frequency tracking stability system, transient frequency search and start, that is, open and stop, can 24

◆ Hours continuous temperature operation

Strengths

◆ Compared with the conventional method, ultrasonic technology has high efficiency and short mixing time;

◆ Ultrasonic technology compared with other processes, no high temperature, high pressure, good safety;

◆ With broad spectrum, wide applicability, most of the liquid can be mixed by ultrasonic wave;

◆ Ultrasonic stirring operation steps are few, the process is simple, not easy to cause pollution, the temperature is low, suitable for the operation of thermal sensitive target components;

◆ Compared with the conventional method, the ultrasonic equipment is simple, the production cost is low, and the comprehensive economic benefit is remarkable;

◆ Compared with some traditional methods, ultrasonic technology is an effective method, it is easier to operate and maintain;

Ultrasonic spray coating

Disperse liquid storage drums

YMUS-FSJB2L

* Nanometer and micron suspensions are dispersed and mixed

The ultrasonic dispersed liquid storage barrel can realize the nano solid particles The dispersion solution is distributed online and stirred to avoid dispersion in the process Liquid agglomeration and precipitation, ultrasonic on liquid or emulsion A suspension of solid particles, ie two liquid substances suspended from each other But not mixed) deserves attention. Ultrasonic wavelength division The dispersive system acting in these suspensions will produce high strength Microjets, but not cavitation, which would have produced The effect of fun. We will detect solids of different sizes A suspension of particles, they're going to be divided into parts,Particles of the same size will be evenly distributed in the liquid.And compared to particles that have not been sonicated, this The particles stay suspended longer. Ultrasound Dispersion is a liquid medium in which a high frequency is added Ultrasonic vibration. Since ultrasound is a mechanical wave, it is not affected by molecules Absorption, which initiates the vibrational motion of molecules as they propagate.Cavitation effect, that is, high temperature, high pressure, micro jet, intense Additional effects such as vibration increase the distance between molecules The average distance, which eventually causes the molecule to break up. Ultrasonic transient The pressure released between the particles breaks the van der Waals forces between the particles,Making the particles less likely to stick together.

Ultrasonic cavitation process

In chemistry, "acoustic cavitation" refers to the formation, growth and implosion of tiny bubbles, cavitation bubbles by compression clasps The expansion cycle consists of a compression loop that causes the positive pressure in the liquid to push the molecules together. In contrast, the expansion cycle Causing negative pressure to pull the molecules away from each other, once the bubbles grow very rapidly until they can no longer absorb the ultrasound Of energy. In this case, liquid will pour in and the bubble will burst. The whole process destroys the liquid phase Student: Student attraction. The cavitation bubbles burst very quickly, these tiny bubbles formed during the ultrasonic treatment It raises the temperature of the fluid around the chamber and creates local hot spots. But the area is so small as toAs for the heat dissipating very quickly. On the other hand, very high pressures are generated during bubble bursting, i.e., approx 1,000 atmospheres. Although the extreme conditions are very limited, ultrasonic treatment produces poles in cold liquids End physical and chemical conditions.

Technical parameters

◆ Product type: ultrasonic dispersed liquid storage barrel

◆ Frequency: 40KHz

◆ Capacity: 0.5-5L

◆ Solution conversion rate: ≥95%

◆ Solution viscosity: ≤50cps

◆ Radiation amplitude: 5-120μm

◆ Solution mixing type: many kinds (customized)

◆ Maximum pressure: < 8bar

◆ Rated power: 1000W

◆ Input voltage: 220V± 10%, 50/60Hz

◆ Transmitter material: titanium alloy

◆ Components: ultrasonic generator, special ultrasonic transducer, special amplitude rod, tool head, shell,

◆ Connecting cables, etc.

◆ Durable temperature: 0~80℃ liquid

◆ Ultrasonic generator: full digital frequency tracking stability system, transient frequency search and start, that is, open and stop, can 24

◆ Hours continuous temperature operation

Strengths

◆ Compared with the conventional method, ultrasonic technology has high efficiency and short mixing time;

◆ Ultrasonic technology compared with other processes, no high temperature, high pressure, good safety;

◆ With broad spectrum, wide applicability, most of the liquid can be mixed by ultrasonic wave;

◆ Ultrasonic stirring operation steps are few, the process is simple, not easy to cause pollution, the temperature is low, suitable for the operation of thermal sensitive target components;

◆ Compared with the conventional method, the ultrasonic equipment is simple, the production cost is low, and the comprehensive economic benefit is remarkable;

◆ Compared with some traditional methods, ultrasonic technology is an effective method, it is easier to operate and maintain;