google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Plasma activation -- Effective surface activation and modification -- Shanghai Yangmi Plasma Treatment

Effective surface activation and modification

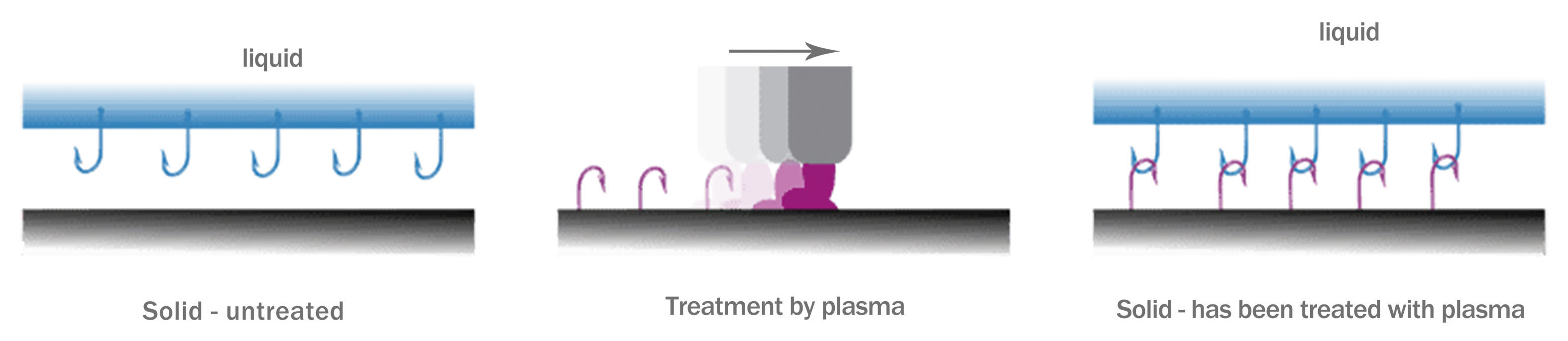

If surfaces must be painted, printed or glued, they need good wettability of the surface to get a good bond. Many surfaces even in a clean state show insufficient wettability exacerbated by impurities. As a result, liquids such as adhesives and inks fall off. This is because the surface tension is very low and insufficient for further treatment. If untreated materials are treated, the result is that paints and varnishes often fail to adhere completely and quickly become loose again, or the bonded parts fall apart. This can be prevented by plasma activation.

Plasma activation of the surface increases its surface energy and produces molecular groups associated with the liquid. This emerges through improved wettability and leads to optimal adhesion of the appropriate liquid.

Plasma processing

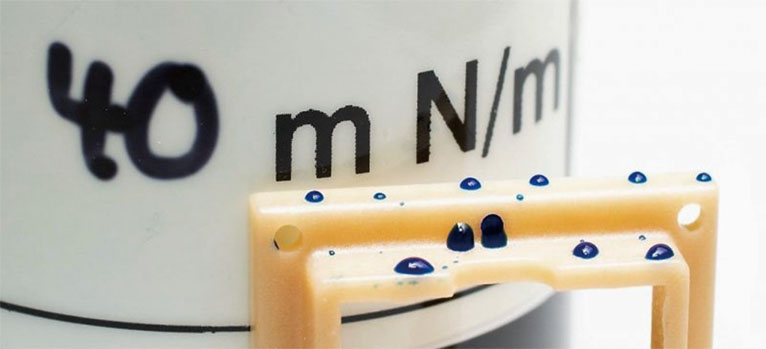

Practical example: Plasma-activated polyphenylene sulfide

In this case, two polyphenylene sulfide components were treated with atmospheric plasma arrays

Untreated PPS components with 40mN/m test ink can not be wetted

Plasma treatment, with 60mN/m test ink achieved complete wetting

Materials that can be activated:

● Metal

● Synthetic materials

● Glass, ceramic, natural stone

● Natural leather, imitation leather

● Natural fiber, wood, paper

Advantages of plasma activation:

● High processing speed and reliability

● No operating costs

● Environmentally friendly treatment without additional chemicals

● Easy online integration and automation

Plasma processing