google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Preparation of gas diffusion layer carbon black and carbon fiber paper coating - YMUS ultrasonic spraying

Ultrasonic spraying technology is an advanced technology for high-precision coating surfaces and can be used to prepare coatings for gas diffusion layer carbon black and carbon fiber paper.

1. Coating characteristics:

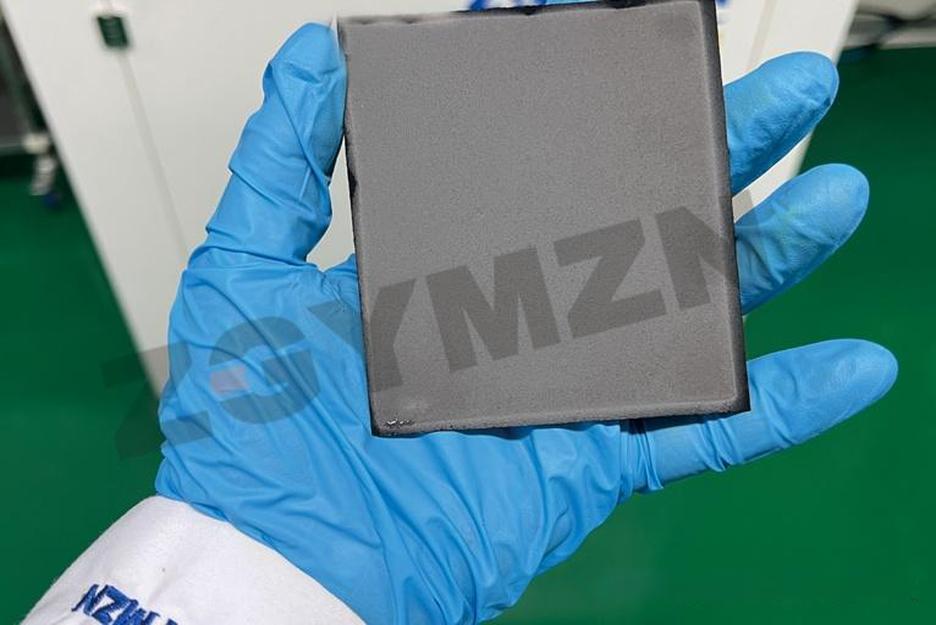

- Gas diffusion layer carbon black coating: Gas diffusion layer carbon black coating is a special coating evenly distributed on the surface of the gas diffusion layer. It can improve the conductivity of the gas diffusion layer and the efficiency of catalytic reactions, thereby improving the energy conversion effect.

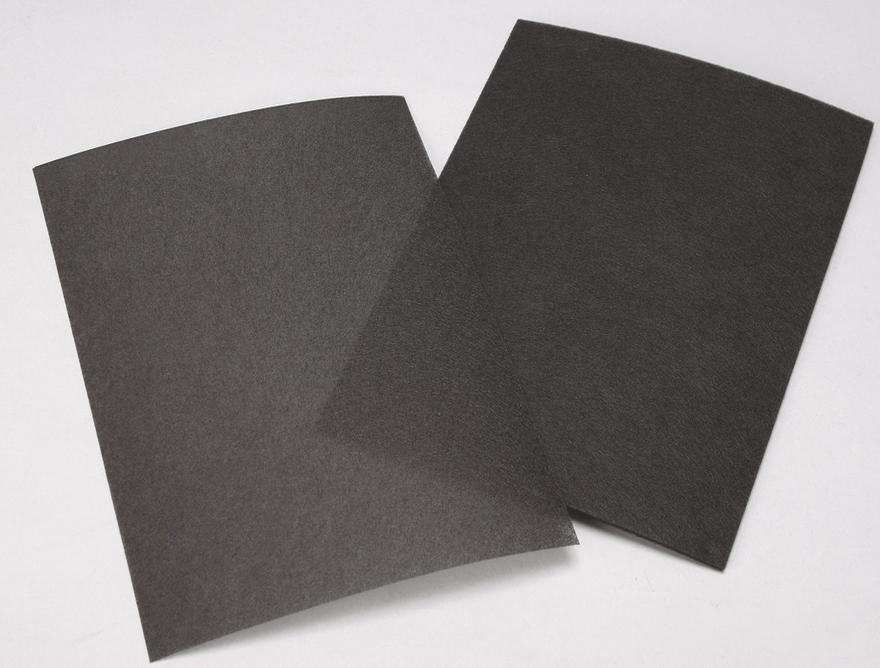

- Carbon fiber paper coating: Carbon fiber paper is a lightweight material with excellent mechanical and electrical conductivity properties. By coating carbon fiber paper, the electrical conductivity and chemical stability of its surface can be enhanced.

2. Advantages:

- High efficiency: Ultrasonic spray technology has high coating speed and uniformity, which can evenly spread the coating on the surface of the substrate, helping to improve the quality and performance of the coating.

- Environmental protection: Ultrasonic spraying technology does not require the use of organic solvents, reduces the emission of harmful solvents, and is more environmentally friendly.

- Wide applicability: Ultrasonic spraying technology is suitable for different types of substrates, including complex shapes and thin film materials, and has good adaptability.

YMUS ultrasonic spray fuel cell catalyst coating sprays a highly uniform, repeatable and durable coating. The anti-clogging technology of YMUS ultrasonic atomization nozzle accurately controls the displacement of the solution to better control the coating thickness. The raw material utilization rate is >95%, which can reduce maintenance and downtime.

YMUS ultrasonic spraying can also be used to coat other metal alloys, nickel, iridium and ruthenium fuel cell catalyst coatings containing metal oxide suspensions to manufacture fuel cell PEM, electrolyzers and solid oxide fuel cells SOFC, etc.