google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Sensors and switches

Optical, inductive, and capacitive sensors are used in millions of applications across all fields of automation. Ultrasonic welding meets the requirements of perfect surface finish, scratch free display plate, tightness and reliable operation of electronic components.

Housing

The highest quality and design requirements are especially applicable to the outer cover. These include strength and tightness, absolute dimensional accuracy, high quality and scratch free surface finish, and clear welds.

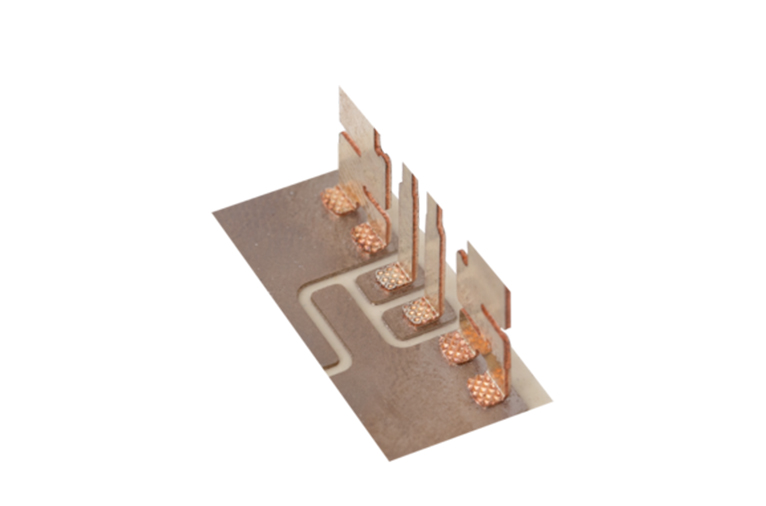

Electrical equipment

In addition to the housing and display components, electronic components can be added by welding or riveting. Ultrasonic welding technology allows energy to be delivered directly into the joint zone. This operation is only feasible in the actual welding process, and can ensure that the joint of the bearing plate and the shell is firm. This approach avoids putting sensitive electronic components at risk.

Cable and quick plug system

Plugs and terminal strips are high quality safety components used in electrical equipment, electronic devices and electrical installations. Strong and fault-free connections of contacts ensure fault-free fit and safe currents. The method of bonding contacts by ultrasonic technology can be used to connect different types of materials.