google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Principle and method of silicon wafer cleaning - wet cleaning - YMMS megaural cleaning

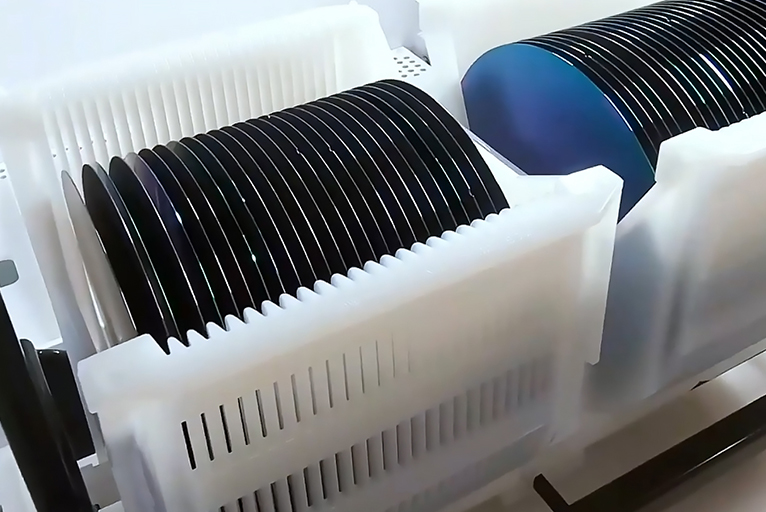

After the silicon wafer is sliced, chamfered, ground, surface treatment, polishing, epitaxial and other different processes, the surface has been seriously contaminated, the purpose of cleaning is to remove the surface particles, metal ions and organic matter pollution.

Common methods and techniques of silicon wafer cleaning

Chemical cleaning refers to the process of using various chemical reagents and organic solvents to react or dissolve the impurities and dust adsorbed on the surface of the object to be cleaned, or accompanied by ultrasonic, heating, megasonic, vacuum and other measures to desorption (desorption) the impurities from the surface of the object to be cleaned, and then rinsing with a large number of high purity cold and hot deionized water, so as to obtain a clean surface.

In the production of semiconductor devices, about 30% of the process is related to silicon wafer cleaning, different process cleaning requirements and purposes are different, must be used in a variety of different cleaning methods and technical means to achieve the purpose of cleaning. Chemical cleaning can be divided into wet cleaning and dry cleaning, among which wet cleaning technology is still in the dominant position in silicon surface cleaning.

Wet cleaning method

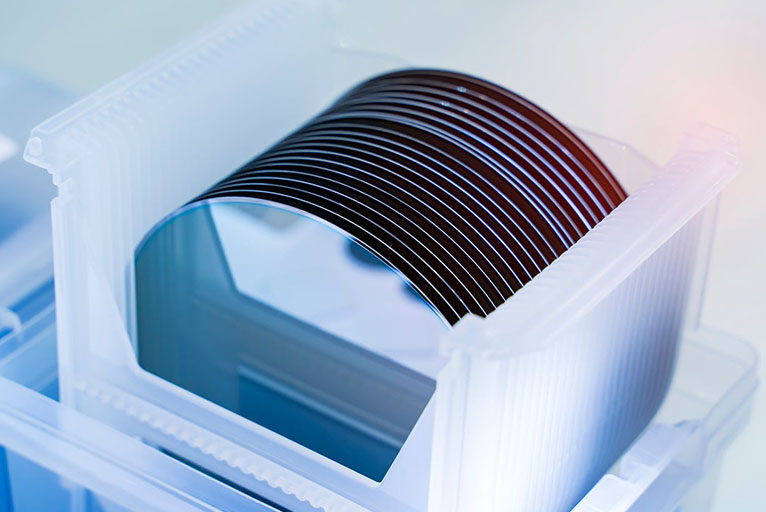

1. Solution soaking method

Solution soaking method is a method to remove surface contamination by soaking the silicon wafer in solution. It is the simplest and most commonly used method in wet chemical cleaning. It is mainly through the solution and the contaminated impurities on the surface of the silicon wafer in the process of soaking chemical reaction and dissolution to achieve the purpose of removing the contaminated impurities on the surface of the silicon wafer.

Using different solutions to soak silicon wafers can achieve the purpose of removing different types of surface contaminated impurities. The efficiency of simple solution soaking method is often unsatisfactory, so when using SC1 soaking, it is often supplemented by heating, ultrasonic or megasonic wave, rocking and other physical measures.

2. Ultrasonic cleaning

Ultrasonic cleaning is a kind of cleaning method widely used in semiconductor industry, the advantages of this method are: good cleaning effect, simple operation, for complex devices and containers can also be removed, but this method also has the disadvantages of large noise, the transducer is easy to break.

The cleaning principle of this method is as follows: under the action of strong ultrasonic wave, the liquid medium will produce a sparse part and a dense part, and the sparse part will produce a nearly vacuum cavity bubble. When the cavity bubble disappears, a strong local pressure will be generated near it, so that the chemical bond within the molecule will be broken, so that the impurities on the surface of the silicon wafer will be desorbed. When the frequency of the ultrasonic wave resonates with the frequency of the vibration of the cavity, the mechanical force reaches its maximum, and a large amount of heat energy accumulates in the cavity, raising the temperature and promoting the chemical reaction.

The effect of ultrasonic cleaning is related to ultrasonic conditions (such as temperature, pressure, ultrasonic frequency, power, etc.), and the improvement of ultrasonic power is often conducive to the improvement of cleaning effect, but for the removal of particles less than 1μm is not good. This method is mainly used to remove large pollution and particles attached to the surface of silicon wafers.

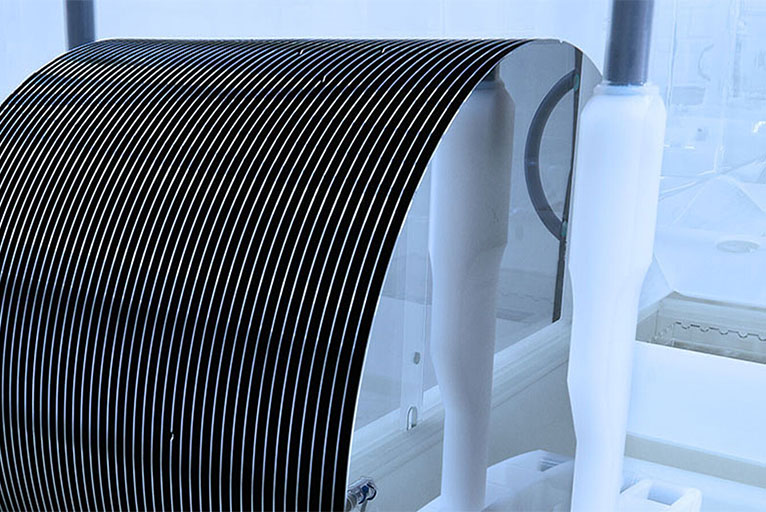

3. Megasonic cleaning

Megasonic cleaning not only preserves the advantages of ultrasonic cleaning, but also overcomes its shortcomings. The mechanism of megasonic cleaning is that the silicon wafer is cleaned by the high energy frequency effect combined with the chemical reaction of chemical cleaning agent. During cleaning, high-energy sound waves with a wavelength of 1.5 μm and a frequency of 0.8 MHZ are emitted by the transducer. The solution molecules are accelerated by the sound wave, and the maximum instantaneous speed can reach 30cm/s. High-speed fluid waves continuously impact the surface of the wafer, so that the pollutants and fine particles attached to the surface of the silicon wafer are forced to be removed and into the cleaning solution.

Megasonic cleaning polishing can remove particles smaller than 0.2 μm from the surface of the wafer, which can not play the role of ultrasonic. This method can play the role of mechanical cleaning and chemical cleaning at the same time. At present, megatonic wave cleaning has become an effective method for polishing.

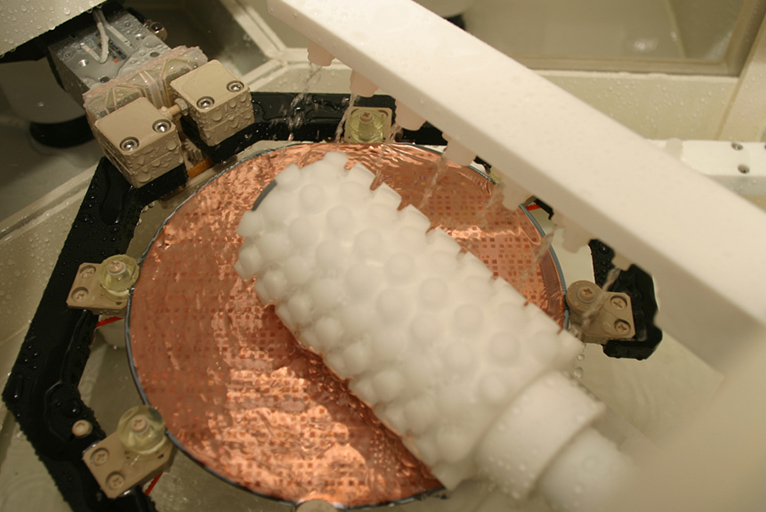

4. Spray cleaning

Rotary spray method refers to the use of mechanical method to rotate the silicon wafer at a high speed, in the process of rotation by constantly spraying liquid to the surface of the silicon wafer (high purity deionized water or other cleaning liquid) to achieve the purpose of cleaning silicon. This method uses the dissolution (or chemical reaction) of the liquid sprayed to dissolve the contamination on the surface of the silicon wafer. At the same time, the centrifugal action of high-speed rotation is used to make the liquid dissolved with impurities off the surface of the silicon wafer in time, so that the liquid on the surface of the silicon wafer always maintains a very high purity. At the same time, due to the spray liquid and the rotating silicon wafer has a high relative speed, so it will produce a larger impact force to remove the adsorption of impurities.

Therefore, it can be said that the rotary spray method has the advantages of chemical cleaning, hydromechanical cleaning, and high pressure scrubbing. The method can also be combined with the drying process of silicon wafers. That is, after the use of deionized water spray cleaning for a period of time, the water is stopped, and the inert gas is sprayed. At the same time, the surface of the silicon wafer can be dehydrated quickly by improving the rotation speed and increasing the centrifugal force.

With the development of semiconductor industry, the requirements for the surface cleanliness of silicon wafers are getting higher and higher, which promotes the development of silicon wafers cleaning technology. YMMS megasonic cleaning technology focuses on the silicon wafers cleaning process. At present, megasonic cleaning process has been recognized in the semiconductor field. We will continue to develop and improve the equipment to adapt to the current development and application field.